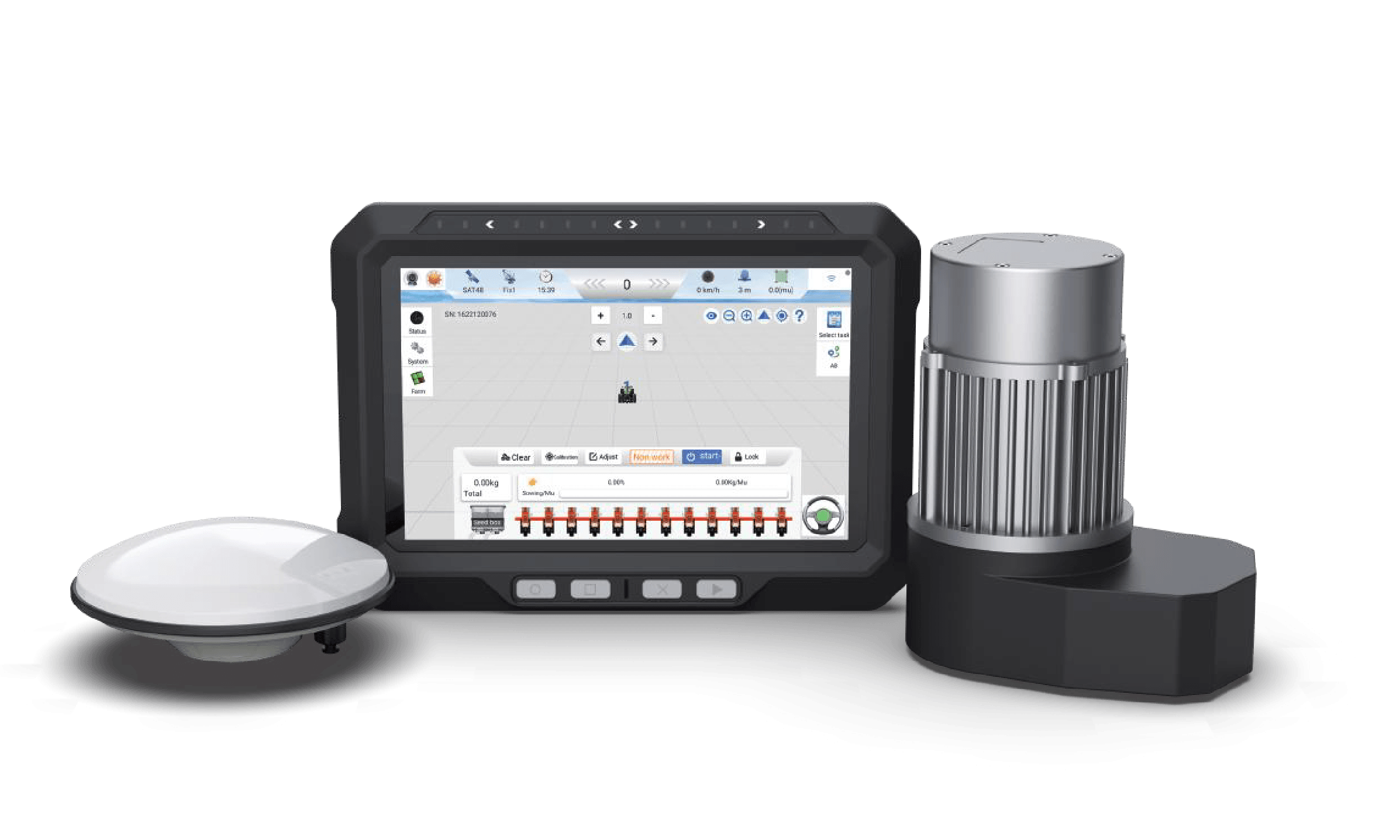

VF200 precision

seeding system

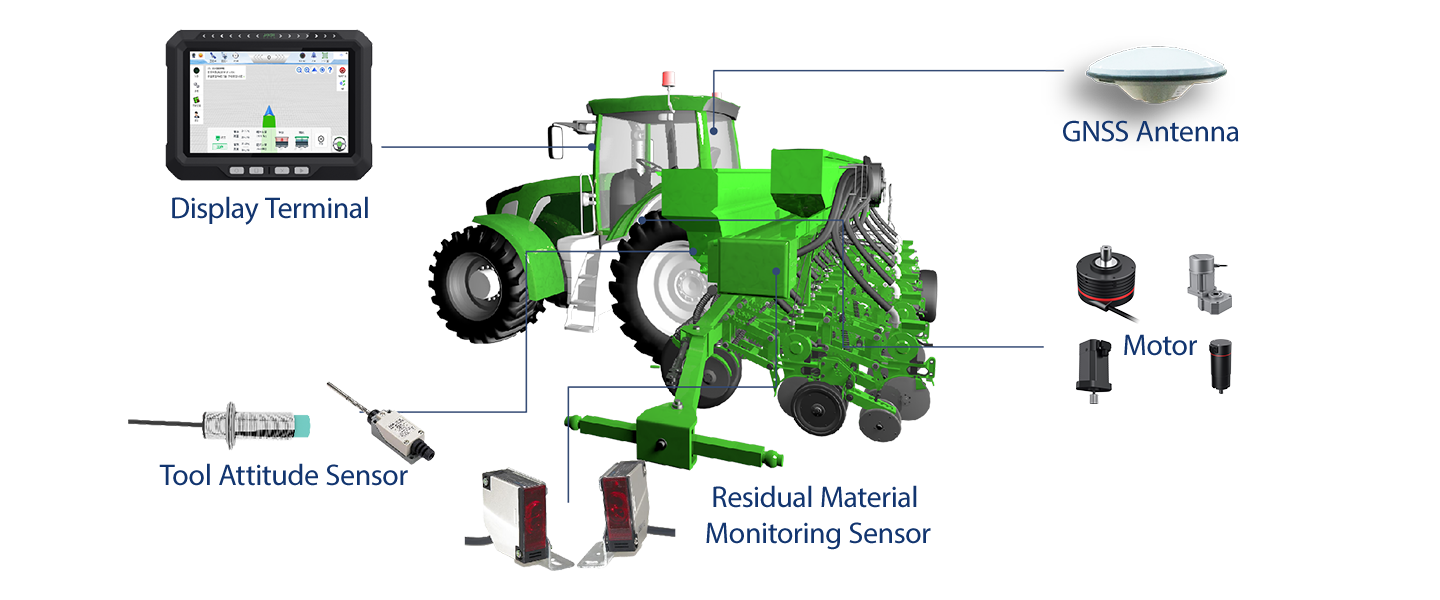

Based on satellite navigation speed measurement technology, this precision control system is designed for seeding and fertilizing machinery. It accurately controls the motor speed in linear correlation with the operating speed, ensuring precise seeding and fertilizing amounts according to user settings. The system boasts high precision and convenient seed rate adjustment and is unaffected by ground conditions, preventing inaccurate seeding caused by ground slippage.

Error rate as low as ±3%

Error rate as low as ±3%

Terrain Compensation

ISOBUS Compatibility

1-12 Motor Expansion

3D Operation Display

Product Features

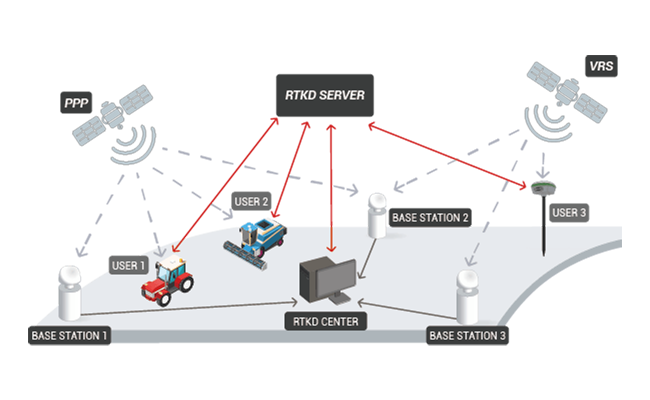

High-Precision Autonomous Operation

Precise automatic control for seeding and fertilization at various speeds, with high accuracy, fast satellite acquisition, and speed measurement accuracy of ±0.02 m/s. Precise control ensures seeding and fertilization errors are within ±3%, with plant spacing errors within ±1.5 cm.

Exclusive Precision Algorithm for Efficient Operation

Precise algorithms enable short headland stop-start distances. The specialized speed processing algorithm ensures uniform seeding unaffected by terrain or slope. Real-time monitoring of seed and fertilizer box levels with a detection accuracy of ±3%, enhancing operational efficiency.

Intelligent Management and User-Friendly Interface

Real-time updates on operation statistics with a user-friendly interface. 3D visualization of operation status allows precise positioning of the seeding area. Operation data is uploaded, enabling real-time cloud monitoring.

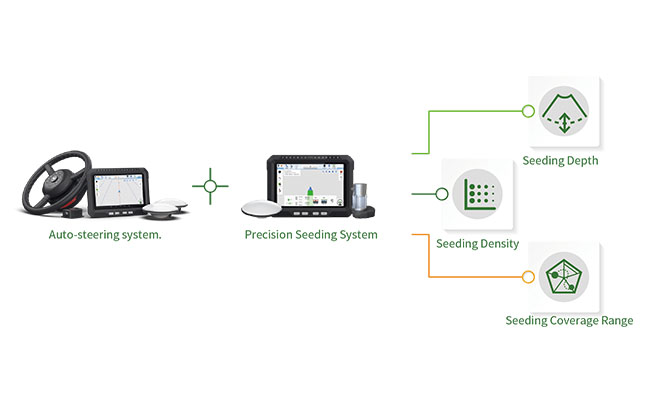

High Compatibility and Broad Application

This system is compatible with many types of machinery, allowing for 1-12 motor expansion. It provides customizable motor control quantity and sectional control. It is compatible with over 90% of seeders on the market and can be used with autosteering, unmanned driving, and seeding monitoring systems simultaneously.

Self-diagnosis for Long-Term Operation

A comprehensive fault detection system that monitors for motor stalling, overcurrent, Undervoltage, overspeed, overload, and Hall sensor faults, ensuring worry-free operation. An innovative manual mode ensures long-term operation even under extreme conditions, such as the absence of satellite signals.

Professional-Grade Hardware for Reliable Use

Professional level electronic control system, capable of working continuously for 24 hours; Multiple types of motors, high speed, capable of achieving low, medium, and high-speed operations; Automotive grade hardware configuration, more reassuring for outdoor operations.

Core applications

Product Parameters

Tablet DisplayPower consumption: ≤ 12.0W Accuracy: ≤ ± 2.5 cm (RTK) Power supply voltage: DC 9-36V Working temperature: -40 ℃ to+70 ℃ Storage temperature: -45 ℃ to+80 ℃ Physical dimensions: 224mm × 160mm × 45mm Weight: 1.36Kg Protection level: IP67 Impact and vibration: MIL-STD-810G RTK Positioning Accuracy (RMS): Horizontal: 8 mm + 1 ppm (RMS) | Vertical: 15 mm + 1 ppm (RMS) Initialization Time: <5 s (typical) Initialization Reliability: >99.9% First Fix Time: <30 s GNSS AntennaFrequency : GPS: L1/L2/L5 BDS: B1/B2/B3 GLONASS: L1/L2/L3 GALILEO: E1/E5a/E5b/E6 QZSS: L1/L2/L5/L6 IRNSS: L5 L-Band Operating Current:≤45mA | Precision Seed Fertilizer Control System ControllerCommunication interfaces: CAN, RS232, RS485 Working voltage: DC9-30V Protection level: IP67 Operating temperature: -35~+65 ℃ Size: 83 × 59 × 33.2mm (excluding cables) Weight:<300g (excluding cables) Drive motorMotor power consumption: 73.8W Power supply voltage: DC9~30V Working temperature: -20 ℃ -50 ℃ Protection level: IP65 |

Related Products

Let's Build the Future with Innovation

We’re here to help you with any questions or inquiries you may have about our products and services. Fill out the form below, and our team will get back to you promptly.

Life & Discovery

We empower farmers with precision and efficient agricultural solutions.

SOLUTION & PRODUCT

Copyright © 2024 Shanghai AllyNav Technology Co., Ltd All Rights Reserved