AF201 Hydraulic

Automated Steering System

The AF201 Hydraulic Automated Steering System adopts a new hydraulic control method, with simple and efficient installation and operation. This system has the characteristics of high precision, easy installation, strong stability, good usability, and strong scalability. It is widely used in agricultural machinery such as tractors, harvesting machinery, plant protection machinery, and rice transplanters, and is a powerful assistant for modern agricultural mechanization operations.

Min Speed 0.1 km/h

Path Planning

Precision Accuracy of ±2.5cm

ISOBUS Compatibility

ISOBUS Compatibility

PPP-RTK&VRS

Hydraulic Control

Terrain Compensation

Product Features

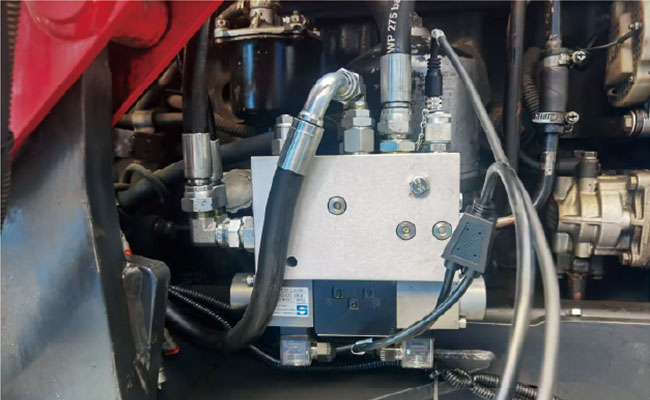

Hydraulic Control

The system seamlessly integrates into the vehicle’s hydraulic steering system without modifying the steering wheel. It allows drivers to control the smart driving equipment easily.

Automated and smart control

The app allows real-time path planning, including turns, straight lines, and curves. It enables quick farming tool alignment and real-time remote monitoring for precise autosteering that saves time and increases efficiency.

Extensive (ISOBUS) Compatibility

When different farming tools with appropriate hardware modules are installed under the ISOBUS, the farming processes from tilling to harvesting are improved. Built-in high-precision terrain compensation brings optimal performance on complex terrains with just one machine.

Advanced Correction Services

A robust antenna guarantees excellent signal stability in unreliable signal conditions. Enjoy accurate operation with up to ±2.5 cm precision using multiple correction services like PPP, VRS, RADIO, and PPP-RTK without needing a base station.

Worry-Free Autosteering

You can operate confidently and efficiently by relying on our market-proven technology backed by 24/7 remote support from a globally deployed service network.

Core applications

Precision Planting

EFFICIENT SPRAYING

Harvesting

Tillage and Soil Preparation

Product Parameters

Tablet DisplayPower Consumption:≤12.0W Power Supply Voltage:DC 6-36V Performance: 8-core processor, 2GHz, onboard 2GB RAM, 32GB storage Operating Temperature:-20℃ to +60℃ Storage Temperature:-40℃ to +70℃ Resolution:1280*800P Screen Size:10.1 inches Weight:1.7Kg Ingress Protection:IP67 Data Interface: RS232:2 port RS485:1 port CAN:2 ports USB 2.0:1 port DI/DO:DI2, DO2 12V DC Output:1 port |

Analog Camera Input:4 ports Steering and Control SectionRated Input Flow: 70L/min Proportional Valve Maximum Output Flow 3CL/min Rated Pressure:210bar Relief Valve Pressure Range: 17-158bar Set Pressure: 80bar Port Size:P/T/A/B/F: M18x15: M/M1/LS: G1/4 Connector Plug: DIN 43650 Control Voltage:DC 12V Power Supply Voltage:DC 9-36V Communication Ports: CAN*2, RS2322, RS485*2 GNSS ReceiverRTK Positioning Accuracy (RMS) Horizontal: 8 mm + 1ppm | Vertical: 15 mm + 1ppm Initialization Time: <5S (typical) Initialization Reliability: >99.9% First Fix Time: <30S Performance Pass to pass accuracy: ≤±2.5cm Frequency Bands: BDS: B1I/B2I/B3I/B1C*/B2b* GPS: L1C/A/L2P(Y)/L2C/L5 Galileo: E1/E5a/E5b/E6* GLONASS: G1/G2 QZSS: L1C/A/L2C/L5 SBAS: L1C/A Data format Differential Data: RTCM V2.X/3.X Data Format: NMEA-0183 Data Update Rate: 20Hz Built-in IMU |

Related Products

Let's Build the Future with Innovation

We’re here to help you with any questions or inquiries you may have about our products and services. Fill out the form below, and our team will get back to you promptly.

Life & Discovery

We empower farmers with precision and efficient agricultural solutions.

SOLUTION & PRODUCT

Copyright © 2024 Shanghai AllyNav Technology Co., Ltd All Rights Reserved